inigence Springback Compensationfor highest part quality

By a reasonable combination of experience and innovation we provide our customers with compensated 3D-CAD-tool data which convince through updatability as well as dimensional and class-A surface quality.

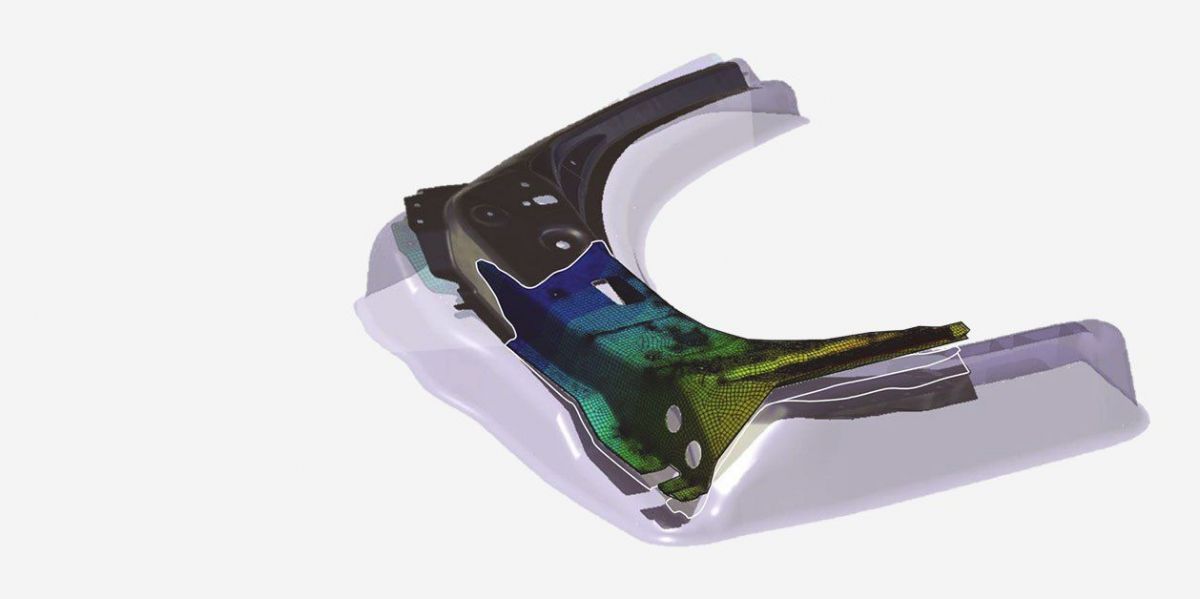

Springback Management: dimensional accuracy in sheet metal forming

The accurate production of complex car body components due to elastic springback still represents a great challenge. We meet this with our self-developed compensation software.

Essential software components of the inigence compensation tool:

- discrete scaling of the drawing tool based on the calculated stress distribution

- standardized compensation strategy – basically usable for all sheet metal parts and materials

- physical compensation algorithm

Benefits of the inigence springback compensation:

- equal in length compensation of springback

- stable part location in all tools along the process sequence

- avoidance of unintended (local) deformations in subsequent operations after drawing

- update capability of the compensated CAD model

and thus

- robust dimensional accuracy

- class-A surface quality

- automated processing of geometrical changes

Our services

- FEM process simulation of the entire manufacturing process with a focus on springback

- analysis of the springback behaviour and process robustness

- discrete scaling of the drawshell

- creation of the compensated tool surfaces

- validation of the compensated manufacturing process by FEM process simulation

- creation of a compensated and update capable 3D-CAD-process plan

Springback compensation: What we need and what you get

Scope of supply (customer)

- 3D-CAD-process plan

- FEM process simulation (optional)

- measuring and clamping concept

Scope of supply (inigence)

- compensated 3D-process plan

- equal in length

- optimized in view of part location in the dies

- class-A surface quality

- update capability

- compensation report in MS PowerPoint